Purpose

To equip industry stakeholders with practical knowledge and actionable strategies for protecting engines by ensuring lubricant product integrity and adopting cost-effective preventive maintenance measures.

Presentations

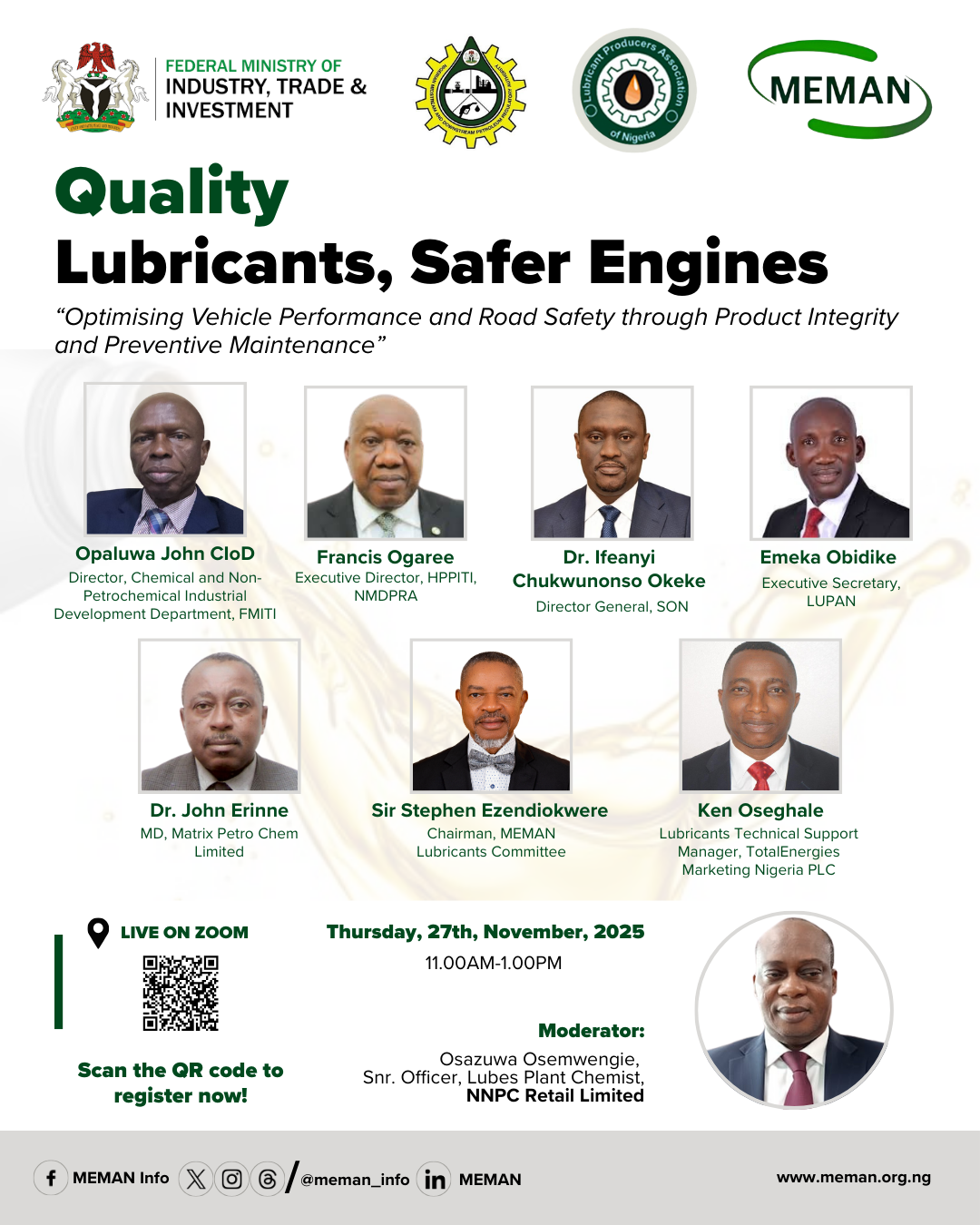

Safety Briefing:

Engr. Moses Okoh – Operations Manager, MEMAN

Opening Remarks:

Sir Stephen Ezendiokwere — Chairman, MEMAN Lubricants Committee

Goodwill Messages:

- Francis Ogaree — Executive Director, HPPITI, NMDPRA

- Paul Pankes — Standards Organisation of Nigeria (SON)

Keynote Address:

Opaluwa John – Director, Chemical and Non-Petrochemical Industrial Development Department, FMITI

Presentations:

- Dr. John Erinne — Managing Director, Matrix Petro-Chem Limited

- Ken Osaghale — Lubricant Technical Support Manager, TotalEnergies Marketing Nigeria PLC

Closing Remarks:

Dr. John Erinne — Managing Director, Matrix Petro-Chem Limited

Moderator:

Osazuwa Osemwengie – Senior Officer, Lubes Plant Chemist, NNPC Retail Limited

Overview

The webinar brought together senior regulators, technical leaders, lubricant manufacturers, and industry associations to examine how product integrity, QA/QC and preventive maintenance support engine reliability, vehicle safety and industrial productivity. The session combined a brief safety moment with opening remarks, two in-depth technical presentations, a standards and enforcement presentation from the Standards Organisation of Nigeria (SON), and a moderated panel and panel discussion. The programme emphasised operational, implementable steps—improving traceability, strengthening QA/QC and lab capacity, and scaling demand-side education—to move the market from price-driven behaviour to quality-first purchasing. MEMAN’s role as convener was central: multiple speakers explicitly thanked and praised the association for assembling the right stakeholders and orienting the event toward practical outcomes and follow-up.

Safety Briefing

The webinar opened with a concise safety moment by Engr. Moses Okoh, Operations Manager, MEMAN, focusing on situational awareness—be present, know exits and hazards, trust instincts, manage fatigue and communicate whereabouts. The moderator then set expectations for a technical dialogue focused on practical outcomes.

Opening Remarks

Sir Stephen, Chairman of the MEMAN Lubricants Committee, opened by stressing that lubricant quality is a strategic requirement for equipment reliability, fleet uptime and road-user safety. He urged collective accountability from regulators, manufacturers, retailers and equipment users. Throughout the event, speakers repeatedly commended MEMAN for convening regulators and industry experts and for orienting the forum toward operational solutions.

Government and Regulator Perspectives (FMITI & NMDPRA)

During the goodwill message, NMDPRA described enhanced surveillance, strengthened licensing conditions for blending plants and the requirement for accredited in-house laboratories, and welcomed MEMAN’s role in coordinating stakeholders toward a national lubricant policy.

The Federal Ministry of Industry, Trade & Investment congratulated MEMAN: “congratulations to the Major Energies Marketers Association of Nigeria for organising this webinar for the benefit of the sector.” The ministry emphasised its support for capacity building, incentives for local blending, investment in laboratory infrastructure and collaboration to accelerate local value addition.

Technical Presentation — Lubricant Quality and The Value Chain (Dr. John Erinne)

Dr. John Erinne provided a value-chain analysis that tied formulation science directly to field outcomes and consumer confidence. He argued that product performance rests on three interdependent pillars—base-oil purity, additive chemistry and disciplined blending—and that QA/QC must be implemented across inbound raw materials, blending processes, storage, distribution and point-of-sale handling. Dr. Erinne listed measurable laboratory parameters used to verify claims and explained how contamination, mislabelling or illicit reprocessing can destroy product integrity regardless of formulation intent. He urged a combined regulator–industry response: more accredited lab capacity, stronger market surveillance and consideration of licensing retail outlets to create clearer retail accountability. Speakers later referenced these recommendations when commending MEMAN for focusing on outreach and on aligning technical guidance with retail-level accountability, reinforcing the association’s emphasis on bridging standards and frontline practice.

Technical Presentation — The Science of Lubrication (Ken Osaghale)

Ken Osaghale delivered a clear, applied explanation of lubrication science that linked base-oil group selection, additive function and blending discipline to engine performance and longevity. He explained how dispersants and detergents prevent deposit formation, how viscosity behaviour affects protective film strength under thermal stress and high RPM, and why additives—though small in volume—are decisive to final product behaviour. Crucially, Mr. Osaghale stressed that correct formulation must be coupled with disciplined blending sequences, robust in-process controls and contamination-free handling; without those, even engineered blends can fail in field service. His practical emphasis reinforced MEMAN’s outreach priority: improving the practices of mechanics, retail staff and service technicians is as important as raising supply-side quality.

Standards, Enforcement and Market Surveillance (SON)

SON presented the statutory and operational tools that underpin market integrity, describing its role in standards development (NIS), conformity assessment, product certification and market surveillance. The agency outlined common contraventions—off-spec imports, recycled containers filled with used oil and solvent blends, fake packaging and false labelling—and explained enforcement workflows that include pre-import checks, market sampling, mystery shopping, laboratory verification and corrective actions such as re-blend demands, confiscation and prosecution. SON recommended practical anti-counterfeit measures—tamper-proof labels, batch coding and visible certification marks—and called for deeper collaboration with industry. Speakers noted that these recommendations mirror MEMAN’s advocacy for traceability and consumer assurance features, and several panellists thanked MEMAN for helping align industry practice with regulatory enforcement priorities.

Panel Discussion

The moderated panel brought regulators, manufacturers and association leaders into a focused exchange on how to operationalise QA/QC, laboratory accreditation and licensing commitments. Questions from participants covered laboratory capacity, batch certification, retail accountability and practical enforcement options. Panellists emphasised the inseparable relationship between supply-side controls and demand-side education: enforcement and lab testing will be less effective unless procurement behaviour among mechanics and retail customers shifts toward quality. Panellists explicitly backed MEMAN’s outreach plans—mechanics’ village engagements, recurring webinars and targeted training—as essential to cultivate quality-first purchasing. These endorsements framed MEMAN’s activities as practical enablers of behaviour change at the point of service.

Key commitments

- Regulators: expand accredited testing capacity, enforce pre-import checks, and apply corrective measures (re-blend orders, seizure, prosecution) for non-compliance.

- Manufacturers / Blenders: maintain robust QA/QC, document in-process controls, support third-party batch certification and adopt tamper-proof packaging and batch coding.

- MEMAN: scale consumer education (mechanics’ villages, targeted webinars) and coordinate stakeholders toward a national lubricant policy.

- All stakeholders: collaborate on traceability systems, lab capacity building and joint awareness campaigns.

Conclusion

The webinar mapped a practicable pathway from technical standards to safer engines by combining formulation integrity, disciplined blending, accredited testing and visible traceability with targeted consumer education. MEMAN’s leadership was explicitly and repeatedly praised during the event: government and regulator speakers thanked the association for convening this cross-sector dialogue, for prioritising practical follow-up and for committing to outreach in mechanics’ communities. One speaker noted MEMAN’s “dedication to public enlightenment and industry excellence.” These expressions of praise were not ceremonial; panellists and regulators treated MEMAN’s convening and follow-up commitments as a meaningful enabler of policy translation—helping to transform regulatory guidance and technical standards into measurable improvement at point-of-use. With regulator enforcement, manufacturer accountability and MEMAN-driven outreach working in concert, participants described a credible roadmap to reduce adulteration, restore consumer confidence and develop a more competitive, integrity-driven domestic lubricant industry.